Scaling Carbon Capture

Why Energy Efficiency is the Ultimate Barrier

Carbon capture isn’t new. For decades, scientists, engineers, and industry leaders have understood that capturing carbon dioxide (CO₂) at scale is crucial to addressing climate change. Yet widespread deployment has stalled. The fundamental barrier is not complexity or even cost in isolation, but energy efficiency.

Despite significant advancements and investment in carbon capture technology, traditional approaches continue to struggle with prohibitively high energy requirements. This inefficiency doesn’t just inflate operating expenses; it also severely limits the locations and industries where carbon capture can realistically be deployed. Until we overcome this challenge, large-scale adoption will remain out of reach and continue to hinder global climate action efforts.

The Hidden Cost of Carbon Capture: Energy

Traditional carbon capture methods, including absorption towers and high-pressure systems, have long dominated the industry. While effective at capturing CO₂, these systems are notoriously energy-intensive, typically consuming more than 2000 kWh per metric ton of CO₂ captured. That kind of energy consumption doesn’t just inflate operating costs; it restricts scalability, making carbon capture inaccessible to all but the most resource-rich locations.

Beyond the immediate financial burdens, this heavy energy footprint often negates some of the environmental benefits of carbon capture itself, especially if the required electricity comes from fossil-fuel-based sources. High energy demands also hinder widespread deployment by requiring extensive infrastructure investments and specialized facilities, making it impractical or impossible for smaller businesses and urban settings—where emissions tend to be concentrated. Furthermore, the complexity and size of traditional energy-intensive systems impose logistical and operational challenges that can extend project timelines and significantly delay carbon reduction efforts.

For carbon capture to play a meaningful role in global climate solutions, efficiency isn’t a nice-to-have, it’s non-negotiable. Only by drastically reducing energy consumption can we unlock carbon capture’s full potential, allowing it to become broadly adoptable, economically viable, and environmentally impactful on a global scale.

Why Energy Efficiency Unlocks Scalability

The direct correlation between energy efficiency and scalability is clear. High energy usage requires extensive infrastructure, massive energy inputs, and substantial ongoing investment. Consequently, traditional carbon capture systems are limited to centralized, specialized sites.

In contrast, highly energy-efficient systems enable a fundamentally different approach. Compact, efficient units can be deployed directly at emission sources, such as dense urban areas, manufacturing facilities, and remote industrial zones. Because of their lower energy requirements, these systems seamlessly integrate into existing energy infrastructures, running effectively on current power grids or renewable energy sources without necessitating expensive power plant expansions or extensive system upgrades. Additionally, significantly reduced energy consumption leads to lower operational costs, making carbon capture financially viable even without substantial government subsidies.

Moreover, improved energy efficiency transforms carbon capture from a niche, costly endeavor into a broadly adoptable, practical solution. It allows businesses and industries worldwide to quickly integrate carbon capture into their sustainability strategies, enabling rapid scaling without the economic and logistical barriers inherent in traditional methods. This widespread accessibility positions energy-efficient carbon capture not just as a promising technology, but as an essential tool in the urgent global effort to reduce emissions.

How CC&C Solved the Efficiency Puzzle

At Carbon Capture & Commercialization (CC&C), we realized early on that the future of carbon capture depended on significantly lowering energy use. After rigorous research and extensive bench-scale validation, our solution now operates at under 100 kWh per metric ton. We have validated this unprecedented benchmark in our laboratory and testing facilities.

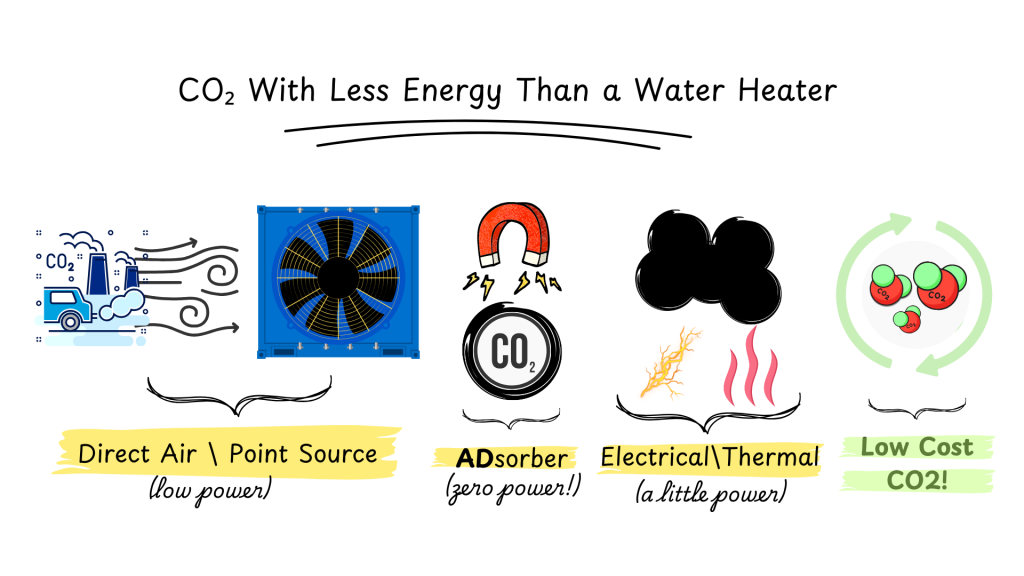

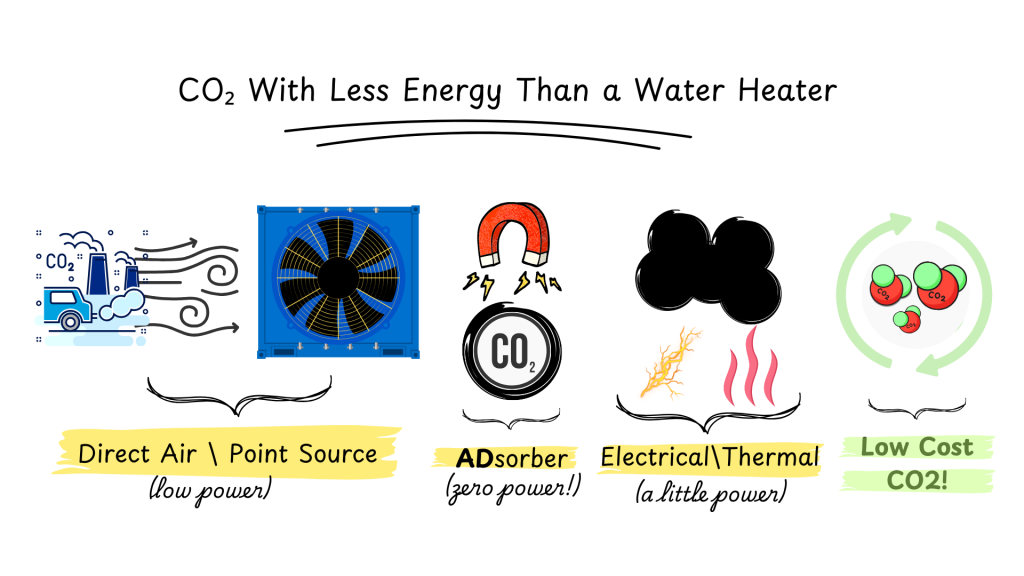

We achieved this breakthrough efficiency by integrating four critical innovations:

- Passive Airflow Capture (CaptureX Pearls): Unlike energy-intensive active capture systems, our proprietary CaptureX Pearls passively adsorb CO₂ directly from ambient airflow, eliminating the need for high-powered fans or compressors.

- Low-Temperature Desorption: Traditional systems require high-temperature thermal cycles (often exceeding 200°C) to release captured CO₂. Our innovative desorption method activates at just above 100°C, dramatically cutting energy demands.

- Graphene-Coated Ceramic Substrates: Our patented functionalized graphene coatings significantly enhance adsorption efficiency and thermal conductivity, further optimizing energy usage during both adsorption and desorption.

- AI-Driven Operational Optimization: By integrating AI and SCADA systems, our units dynamically optimize operating cycles, reducing downtime and unnecessary energy consumption.

Combining these technologies has enabled us to set a new industry standard, redefining what’s possible for carbon capture energy efficiency.

Strategic Impacts for Industry and Business

Energy efficiency isn’t just a technical achievement, it’s a strategic advantage that fundamentally alters the economics and business cases of carbon capture. Achieving an energy use of less than 100 kWh per metric ton means our units can now be deployed profitably even at smaller scales. Businesses no longer face prohibitively expensive infrastructure projects spanning decades; instead, they can quickly and economically integrate carbon capture into their existing operations.

The affordability and compactness of our solution create expansive market opportunities across diverse industries. Sectors such as Enhanced Oil Recovery (EOR), cement production, agriculture, and steel manufacturing already represent substantial, multi-billion-dollar global markets for captured CO₂. Our efficient and scalable technology perfectly meets their demands, creating immediate and tangible economic benefits.

Our solution seamlessly aligns with existing policy frameworks and incentives, further enhancing these advantages. Regions including the EU, UK, and California offer robust financial incentives for energy-efficient carbon capture, notably through the EU Emissions Trading System (ETS), Section 45Q tax credits in the U.S., and California’s Low Carbon Fuel Standard (LCFS). CC&C’s technology integrates perfectly within these frameworks, multiplying its economic value and appeal to stakeholders.

Lastly, our energy efficiency positions CC&C distinctly ahead of competitors, most of whom operate at significantly higher costs. These costs are typically between $350 and $900 per metric ton. With our technology achieving under $100 per ton, businesses benefit from dramatically faster payback periods, substantially lower total cost of ownership, and greater flexibility in deployment. This competitive differentiation underscores our technological advantage and transforms carbon capture from an ambitious idea into an achievable business reality.

The Bottom Line

Efficiency isn’t merely a performance metric; it’s the cornerstone of scalability. At CC&C, we’ve demonstrated at bench and lab scale that carbon capture can be compact, affordable, and ready for real-world use.

We’re transitioning from laboratory validation to targeted industry adoption and actively seeking forward-thinking collaborators for our pilot program. Participants gain early access to groundbreaking technology, reducing their CO₂ emissions effectively and economically, with minimal risk. In return, these partnerships help us fine-tune our systems under actual operating conditions, ensuring mutual success and measurable environmental impact.

If you’re ready to integrate practical carbon capture into your operations and sustainability strategy, reach out today. Especially welcome are organizations in high-emission sectors like EOR, cement, steel, and agriculture.

Together, let’s move carbon capture out of the lab and into the real world where it matters most.

Safe Harbor Statement:

This article contains forward-looking statements regarding CC&C’s technologies and anticipated impacts. Actual results may differ due to technological advancements, market conditions, and regulatory developments. CC&C assumes no obligation to update these statements as new information becomes available.